Process Equipment and

Air Handling Specialists

Experienced engineers serving the US and Canada for over 35 years.

Experienced & Effective

Engineering Solutions

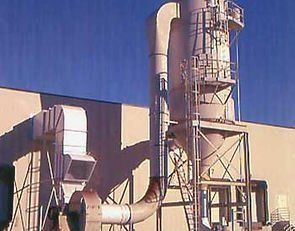

KVA Engineering brings 35 plus years experience to all facets of process equipment, pneumatic conveying and dust collection design and installation. KVA can also provide technical expertise in mechanical engineering and can provide a complete turnkey project or assist your engineering staff on the correct selection of process equipment for your exact plant needs. Call today so we can help you with your industrial dust collection solutions!

We Meet Your Needs

A Family-Owned Business

KVA Engineering offers consultation, installation, service checks, system upgrades, warranty and plant maintenance cleaning. We also offer engineered design solutions to meet your process equipment and air quality needs. KVA Engineering would like to provide you with all the parts, materials and services your application or system needs.

Our Services

We Provide Consultations

KVA Engineering can provide your company with sound technical advice and provide cost-effective solutions to your dust collection, pneumatic conveying or vacuum needs, spark detection, and material handling.

VA Engineering offers the best innovative products for solving indoor and outdoor air pollution problems. Our equipment and systems meet or exceed OSHA, PEL, NFPA, EPA, FDA compliance, and other regulatory agencies. We provide:

- Source capture or general capture systems for efficient pollution control.

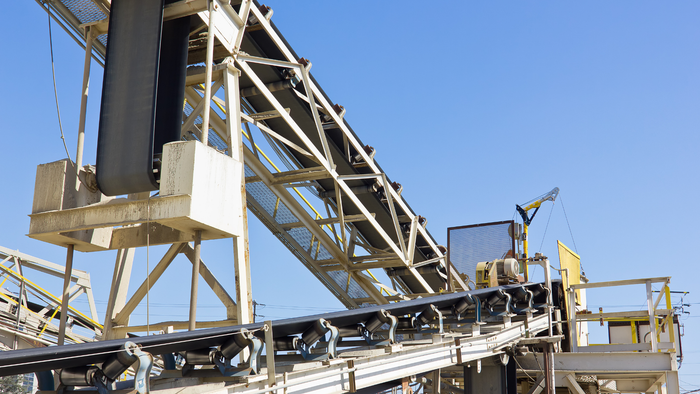

- Pneumatic conveying design for positive and negative dilute phase conveying systems.

- Hood and duct-work design.

- Existing system surveys to determine your present capabilities, and what is required to satisfactorily bring your system into compliance.

- Existing filter survey to determine any deficiencies of your present system.

- Equipment installation analysis.

No Insulation Project Is Too Small

Efficient System Upgrades

KVA Engineering can upgrade your current system to provide more capacity for your plant. This would include fan, filter, duct-work or pneumatic system upgrades.

To expand an existing system, KVA Engineering can upgrade the existing filter unit if it has additional capacity or KVA can install an additional filter unit.

Let KVA Engineering come in and do a complete plant survey of your dust collection needs. We then can examine your dust collection unit to see if it can be expanded or if we need to add an additional filter.

KVA can complete this with a report to your company.

Plant Maintenance Cleaning

Plant cleaning to meet OSHA’s requirements for measurable dust on surfaces in the plant. Confined space clean-up for hazardous locations such as:

- Explosive Dust Environments

- Flammable Dust Environments

- Confined Space Locations

- Overhead Trusses, Ductwork Storage Areas

- Dust Collection Units

- Hazardous Dust

Let KVA Engineering provide a complete proposal to have our crew come in with explosion proof equipment, remove the hazardous dust from your storage, dust collector, work area or overhead truss work. KVA Engineering deals primarily in dust, not liquid removal.

Providing the Parts You Need

Materials and Services

KVA Engineering would like to provide you with all the parts, materials and services your application or system needs. Click on the pictures to complete an order request form(s) to order parts for your application. We accept Visa, Mastercard and American Express!

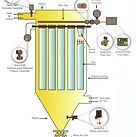

Bag Filters

We have prepared a spreadsheet to help you in your decision and ordering of the correct bags for your application.

Prekote

Increases initial efficiency and protects the filter during start up.

Cartridge Filters

Air Filter Cartridges

100% Cellulose

100% Spun Bond Polyester

Cellulose Flame Retardant

80/20 Cellulose/Polyester

Bottom or Top Removal

Other Parts

Airlock wipers, Diaphragm Valve Kits, Solenoid Valve Kits, Visualite Powder, Pressure Gauge Kits, V-Belts & more!

Service Checks

If you'd like to request a service check, or want to learn more, complete our contact form and click send. If you'd prefer to call us, we can be reached at 763-478-3015.

KVA Engineering can come to your facility and examine your process equipment and provide a full, complete report on deficiencies that need attention.

Our bonded and insured technicians will perform the following inspection checks monthly, bi-monthly, or quarterly:

- Overall status of the dust collector(s)

- Fan Vibration Readings

- Compressed Air System for leakage

- Fan Motor Amperage

- Regulator Pressure

- Fan Belts Wear

- Air Shut Off Valve sealed and working properly

- Fan Damper in working order

- Solenoids firing properly

- Emissions Monitor working (if applicable)

- Diaphragms Valves Firing Properly

- Sealed Drums and any connections

- Couplings Sealed

- Screw Conveyor (if applicable)

- Magnehelic working properly

- Rotary Valve Discharge

- Bag/cartridges installed properly

- Gear motor is working

- Bearing replacement

- Bag and Cartridge Change Out

Send Us a Message

Need a system check? We’re here to help. Send us a message and we’ll be in touch!

Frequently Asked Questions

Got a question? We’re here to help.